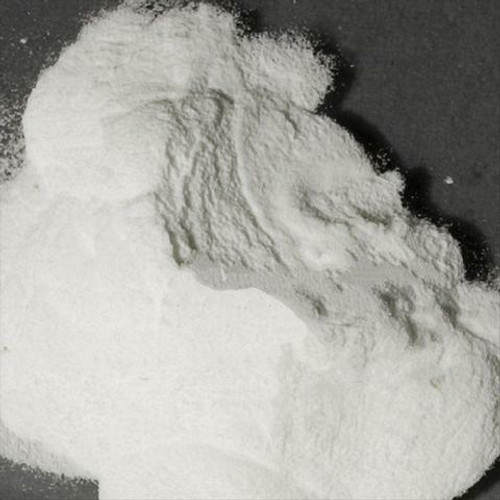

Alumina (properly called aluminum oxide) powder as used in ceramics can be a white granular material (like table salt) or an exceptionally fine silky white and dense powder (depending on the type and processing method).

There are three general types of alumina: Hydrated, calcined and tabular. Within each of these there are many grades. The magnitude of industrial energy, processing and know-how put into alumina production becomes evident when one sees the great variety of grades available and realizes what it takes to make these. Aluminas vary in the amount of soda (Na2O), iron (Fe2O3) and silica (SiO2); ultimate crystal size, chemical purity and the physical properties of the powder or granules. Calcined aluminas are generally used in porcelain and whiteware bodies, low soda for electronic applications. Super high purity grades (99.99% pure) for optical and electronic applications are made using non-Bayer processes such as ammonium aluminum sulfate, aluminum chloride or aluminum alkoxide. Typical bodies for use in electronic applications may contain 95% or more alumina. When hardness is required (e.g. for abrasive) purity (e.g. 99%) is considered one indicator.

Alumina oxide ceramics have very high melting temperatures and hot and cold mechanical strength and are good for abrasion and corrosion resistant applications where heat resistance is also important (compressive strength may average 250,000 psi but high purity mixes can be up to 500,000 psi!). They are among the strongest, hardest and most abrasion resistant of all ceramic materials. The strength of alumina ceramics is exceeded only by silicon carbide, boron carbide and diamond; the abrasion resistance only by diamond. They also have outstanding electrical and thermal properties (like high dielectric strength, high electrical resistance, low dielectric loss). Spark plugs, for example, are made using a high alumina porcelain (about 90%) for its insulating properties coupled with its strength, heat and thermal shock resistance. High alumina ceramics (99%+) can provide such good resistance to chemical attack that they can resist hydrofluoric acid and molten alkalis and alkali vapors. The chemical inertness of these same bodies make them ideal for making valves and seals exposed to severe corrosive and abrasive conditions. Alumina ceramics also resist the effects of radiation that can destroy other materials. Further, alumina ceramics maintain most of the above properties at elevated temperatures. Many of alumina's outstanding properties can be further enhanced by specific manufacturing methods and additives.

Since alumina is by nature refractory, alumina ceramics and alumina refractories might seem like redundant terms. However the former refers to alumina containing bodies that have a fine grain structure and dense matrix and whose purpose is more than just resistance to temperature. The term 'high alumina ceramics' generally refers to mixes containing 85+% alumina. Some high demand applications such as furnace tubes and lab ware cross the boundaries of both alumina ceramics and alumina refractories, these are often made from 99.8% alumina mixes. 99.9% aluminas are used in super duty applications like nuclear ceramics and cutting tools. Alumina and alumina mixes can be dry pressed, isostatic pressed, hot pressed and extruded, tape cast and injection or compress molded. However most processing and firing methods involving alumina have to be adjusted compared to those used for more traditional ceramic mixtures. High alumina bodies lack forming properties so organic and inorganic lubricants, binders, electrolytes and plasticizers are used (e.g. methyl cellulose or HPMC binder). We have had good success using 3-3.5% VeeGum, if the alumina is fine enough this produces a material that can be formed like potter's clay.

While greater quantities of alumina often improve the properties of mixes in which they are being used alumina is expensive and greater quantities require higher firing. Thus a compromise between performance and cost must be reached.

The mineral corundum yields native alumina while the hydrated minerals gibbsite, diaspore, and boehmite are also found in nature. Alumina occurs as silicates in clays, feldspars, kyanite, and many other minerals. However, the principle sources of purified and hydrate alumina are native bauxite and laterite deposits.